REAL GOOSE DOWN OR SYNTHETIC PADDING?

Let's clarify!

How to consciously choose the best padding solution for your clothing?

To begin with, we must ask ourselves if we are interested in joining the global sustainable movement. If the answer is affirmative and we share values such as environmental awareness and resource conservation, it’s crucial to be aware that real down has almost no impact on the pollution of our planet, while synthetic padding, also known as polyester, is one of the most polluting materials in the world.

Having made this ethical decision, the choice of padding becomes a crucial aspect in the design of winter garments. It must not only provide warmth and comfort, even in extreme weather conditions, but also offer benefits such as reduced bulk, ease of washing, and long-term maintenance.

Both real down and synthetic padding have their own set of advantages and disadvantages, so it’s essential to carefully consider the pros and cons before choosing either option.

It’s important to note that the decision to use one material over the other is influenced by various factors, including the budget, personal preferences, desired comfort, and the functionality of the final product.

Real goose down and synthetic padding: the differences

Contrary to common perception, real down is a natural material derived from the recycling of geese and ducks raised for food consumption. Yes, you heard that right! This means that the down is simply a by-product of the global food industry, meaning that the animals are neither bred nor sacrificed for their feathers.

Synthetic padding, on the other hand, is produced by the petroleum industry, which is known as one of the most polluting industries in the world. Even when using recycled PET to produce synthetic padding, significant environmental problems arise. First of all, the recycling of PET is a highly complex and costly process, not to mention that, once plastic bottles are recycled into flakes used to make synthetic padding, it is unlikely that this material will be further recycled, as there is no system for large-scale recycling of synthetic textile fibers.

Synthetic padding: the advantages

Synthetic padding offers only one true and unique advantage: cost. Being an oil output, synthetic padding has become an economical alternative to real down on the market: it is easy to work in the textile industry and has insulating power (thermal insulation) that mimics real down, which makes it able to keep the warmth of those who wear it.

However, it does not have the same properties as natural down. Synthetic padding, in fact, is not as comfort as natural padding, and its synthetic and non-breathable material can cause excess heat and therefore excessive sweating during use, which can later turn into a feeling of cold for the wearer. Furthermore, it is difficult to recycle and is derived from non-renewable sources, making this padding a highly polluting product that depletes natural resources.

Real down: advantages

Real down offers numerous advantages as padding for winter clothing. Firstly, it has a high capacity to maintain body temperature constant, making it one of the most comfortable solutions available on the market while also being breathable, thus avoiding generating sweat. Additionally, it is light, soft to the touch and highly compressible, making it easy to insert into tight spaces such as backpacks or suitcases. Real down also has a long lifespan of many years without ever diminishing its natural characteristics, and once recycled, it does not lose its insulation power.

Difference between goose and duck down

In terms of performance, there are no significant differences between goose and duck down. However, we can find some visual and olfactory differences that distinguish them. Goose down generally appears whiter but may exhibit black spots, whereas duck down tends to have a slightly “yellowish” hue and in its raw form has a more persistent odor than goose down. Nonetheless, the choice between goose and duck down is mainly a matter of prestige and individual brand choice: some companies prefer to use goose down for its reputation for higher quality, but from a performance point of view, both options are very valid, and whoever wears them will not experience any practical advantage in choosing one over the other solution.

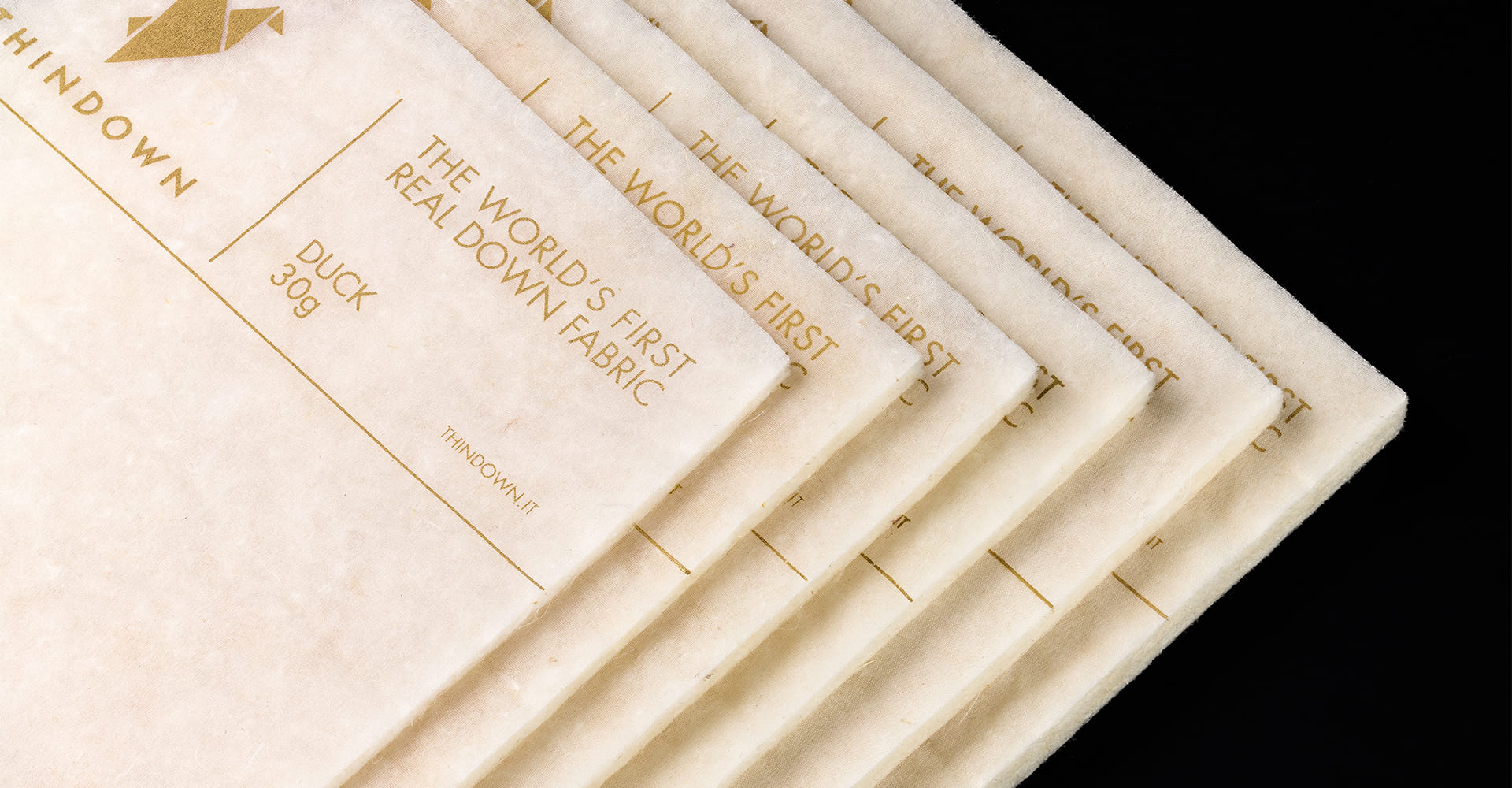

Thindown: the evolution of loose down

Are you aware that loose down can be transformed into a unique and lightweight fabric? THINDOWN, 100% Made in Italy, is the world’s first real down fabric. A patented product that seamlessly combines all the benefits of real down with the ease of use of traditional padding on the market. An innovative solution that preserves all the natural properties of down within an incredibly thin material.

Characteristics and advantages of Thindown

Traceable throughout its production chain, from breeding to final product, Thindown has several certifications to ensure its commitment to responsible practices. All products made with virgin down are RDS (Responsible Down Standard) certified guaranteeing ethical sourcing. At the same time, all lines made with post-consumer recycled down are GRS (Global Recycled Standard) certified. But that’s not all! In addition to these certifications, Thindown goes the extra mile in ensuring safety and environmental friendliness. It is OEKO-TEX® Standard 100 Class 1 certified, signifying that it is free from harmful chemicals and dyes. This certification makes Thindown suitable even for infant clothing, ensuring the highest standards of safety and quality.

Thindown, functioning like conventional padding, is ready to be cut and sewn together with the outer fabric and lining of the garment with a single pattern, simplifying the manufacturing process of down garments. A real revolution in the world of down padding.

Versatile and easy to customize, thanks to its structure, Thindown allows any type of processing, thus extending the use of down to a whole range of product categories outside the traditional scope of application (hats, gloves, shoes, etc.).

Thanks to the uniform distribution of down, Thindown provides a homogeneous barrier against the passage of cold air, and thanks also to the absence of horizontal seams, it avoids the movement of down from one point to another on the garment, a discomfort typical of traditional down jackets available on the market.

Thindown can be processed like any fabric, even in small workshops not specialized in down, and thanks to its compact structure, it improves the working conditions of workers, as the down, not being loose, reduces the risk of inhalation through the airways.

In terms of warmth, Thindown outperforms both polyester and traditional down, being 4 times warmer than polyester and 2 times warmer than conventional down. Additionally, Thindown is easy to maintain: it can be easily washed at home in the washing machine and dryer.

Thindown fabrics

Thindown is available in different down qualities and weights to meet the specific needs of each brand, from 30g to 150g.

Discover Thindown Recycled, the fabric made of 100% post-consumer recycled down, or give maximum comfort to your garments with Thindown + Sorona®, the perfect combination of science and nature, thanks to the blend of Thindown and Sorona® fibers.

Explore the captivating product lines of Thindown and choose the one that best suits your needs, unlocking a new level of performance and comfort for your garments.